china 8-6 rubber slurry pump

Latest articles

All manufacturers are consistently involved in product development in the long and short term. Customers should expect to benefit from these developments in a number of ways: increased efficiency, increased reliability, reduced operating costs, or a combination of both.

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read More- Installation flexibility - The submersible slurry pump is available in a variety of mounting models, including portable and semi-permanent (also easy to move as it can be freely suspended from a chain or similar device without having to be bolted to the ground/floor, etc.).

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read MoreDetermine the operating parameters of the pump.

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read MoreIt is also important to consider the chemical compatibility of the slurry with any elastomers in the pump. Once the nature of the slurry and the components of the different types of pumps have been addressed, you can select potential candidate slurry pumps for the application.

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read MoreThere are several types of slurry pumps, the most common being: centrifugal and volumetric pumps.

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read MorePacking the box seal

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read MoreWZ series slurry pumps are new type wear resistant & corrosion resistant slurry pump for the complexity and specificity of coal, power plant, metallurgy, chemical, building materials and other industries.

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read MoreDredge pumps are designed to transfer large quantities of fluids and solids.

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read MoreHow does a dredge pump work?

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read MoreDetermine the operating parameters of the pump.

china 8-6 rubber slurry pump...

china 8-6 rubber slurry pump 【china 8-6 rubber slurry pump】

Read More

Popular articles

- When the slurry pump working, pump parts are easy to be impacted, wear, and corrosion, etc. Therefore, the liner of the slurry pump uses wear-resistant material, such as high chromium alloy, rubber. The wear-resistant materials can effectively reduce the wear parts of the pump. So most of the slurry pump is a wear-resistant slurry pump in the current market.

- - Portable and low maintenance - There are no long or exposed mechanical shafts between the motor and worm gear, which makes the submersible pump more portable. In addition, because there are no long or exposed mechanical connections between the motor and worm gear, less maintenance is required and operating costs are significantly lower.

- 3.Basic pump components such as impeller size and design, materials of construction and discharge configuration must be considered to ensure that the pump can withstand the wear and tear caused by abrasive slurries. Slurry pumps are typically larger in size compared to low viscosity liquid pumps and often require more horsepower to operate due to their lower efficiency. Bearings and shafts must also be more robust and durable.

- The basic mechanical seal flushing programme is very simple. It requires that a clear/clean fluid (usually water) is introduced into the space between the actual seal and the impeller side outlet restriction. The flushing fluid is introduced at a pressure higher than the pumping pressure, thus ensuring positive outflow/flushing of the mechanical seal and a clean operating environment.

- If you have experience pumping slurries, you know it's not an easy task. Slurries are heavy and difficult to pump. They cause excessive wear on pumps and their components and are known to clog suction and discharge lines if not moving fast enough. Most importantly, it’s a challenge to make slurry pumps last for a reasonable amount of time. But, there are a few things you can do to extend the life of your slurry pump and make pumping slurry less of a challenge.

- Slurry pumps can be used for.

Latest articles

-

Particle size, shape and hardness (impact on wear and corrosion potential of pump components)

-

>Slurry Pump VS Mud Pump

-

Low slurry flow rates

-

Slurry Pump Selection

-

Selecting the right pump for slurries is critical to get the most bang for your buck. Basic pump components, such as the impeller size and design, material of construction, and discharge configurations must be considered to ensure the pump will hold up against the wear caused by an abrasive slurry. Slurry pumps are generally larger in size when compared to low-viscosity liquid pumps and usually require more horsepower to operate because they're less efficient. Bearings and shafts must be more rugged and rigid as well.

-

Dredge Pump

Links

- The Pusher Leg Rock Drill, as its name suggests, is a robust and advanced drilling device specifically designed for hard rock excavation. It combines the power of a hydraulic system with the precision of a mechanical engineering marvel, making it a game-changer in the industry. This drill not only increases productivity but also ensures safety and sustainability in operation.

- Furthermore, FRP fittings contribute to environmental sustainability. Their longevity means fewer replacements and less waste generation over their lifetime. Additionally, the manufacturing process of FRP components often requires less energy compared to producing metal counterparts.

- It is also worth noting that the cost of a jackhammer can be a worthwhile investment for businesses and contractors that frequently require heavy-duty demolition and construction work. A high-quality jackhammer can help increase productivity, efficiency, and overall project quality, ultimately saving time and money in the long run.

jack hammer price. Shipping costs have risen due to factors such as fuel prices and international trade disruptions. These additional costs are often passed on to consumers, resulting in higher prices for power tools like the Jack Hammer.

jack hammer price. Shipping costs have risen due to factors such as fuel prices and international trade disruptions. These additional costs are often passed on to consumers, resulting in higher prices for power tools like the Jack Hammer.

Their ability to maintain consistent performance under high temperatures and pressures makes them ideal for drilling deep into the earth's crust Their ability to maintain consistent performance under high temperatures and pressures makes them ideal for drilling deep into the earth's crust

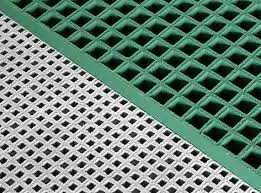

Their ability to maintain consistent performance under high temperatures and pressures makes them ideal for drilling deep into the earth's crust Their ability to maintain consistent performance under high temperatures and pressures makes them ideal for drilling deep into the earth's crust Its open-grid design allows for water and debris passage, ensuring a safe walking surface Its open-grid design allows for water and debris passage, ensuring a safe walking surface

Its open-grid design allows for water and debris passage, ensuring a safe walking surface Its open-grid design allows for water and debris passage, ensuring a safe walking surface

The non-conductivity of FRP also adds an extra layer of safety by preventing electrical hazards The non-conductivity of FRP also adds an extra layer of safety by preventing electrical hazards

The non-conductivity of FRP also adds an extra layer of safety by preventing electrical hazards The non-conductivity of FRP also adds an extra layer of safety by preventing electrical hazards

Some jack hammers come with interchangeable chisels, making them versatile for various tasks Some jack hammers come with interchangeable chisels, making them versatile for various tasks

Some jack hammers come with interchangeable chisels, making them versatile for various tasks Some jack hammers come with interchangeable chisels, making them versatile for various tasks Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic

Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic Twist bits, for instance, are ideal for general-purpose drilling in wood, metal, or plastic